Mounting Options

Formed Plastic Letter Mounting options

1A-Plain

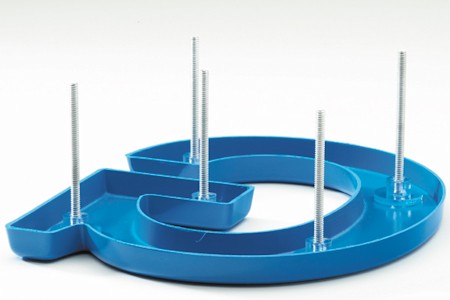

2A-Stud

2B-Pad

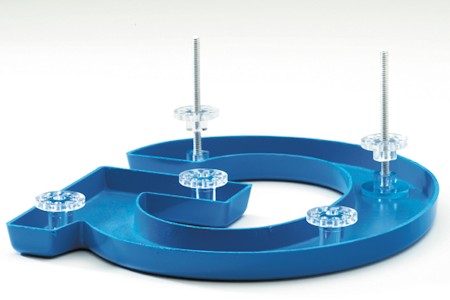

2C-Combo

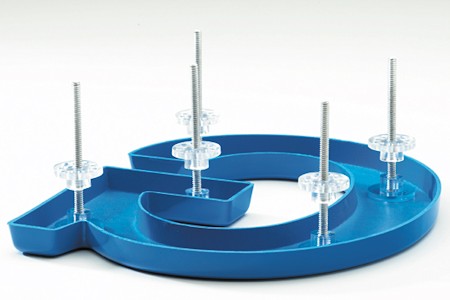

2D-Combo-All

2F-Flange

Outer Bracket

Standard**

For most formed plastic installations, we recommend 2C-Combination mount. This combination gives you the strength of the stud mount while requiring the installer to only drill half as many holes. 2C-Combination mount is included in the pricing listed on the price page.

** Standard mounting In-Line for rail, brick or block

1A-PLAIN MOUNT No mounting blocks or hardware included. 10% discount.

2A-STUD MOUNT Threaded blocks are solvent bonded to the letter backs to receive a 10-24 stud. Silicone adhesive is applied to the studs and into the drilled holes when installing. Drilling pattern is required for this installation.

2B-PAD MOUNT

Threaded blocks are solvent

bonded to the letter backs to

receive the perforated pad.

Silicone adhesive is used to

adhere the perforated pads to

the installation surface. Spacing

guides are available for this

installation. ** Most letters 9” and

under will have perforated pads

bonded directly to the letter back

and will have a slight stand-off.

2C-COMBINATION MOUNT Threaded blocks are solvent bonded to the letter backs. The top portion of the letter receives stud through pads and the bottom pad only. Mounting procedure is the same as 2a Stud with the addition of securing pads to the installation surface with silicone. Drilling pattern is required for this installation. ** Most letters 9” and under will have perforated pads bonded directly to the letter back and will have a stand-off.

2D-COMBINATION ALL MOUNT Threaded blocks are solvent bonded to the letter backs. All mount locations receive a stud through pad. Mounting procedure is the same as 2a Stud with the addition of securing pads to the installation surface with silicone. Drilling pattern is required for this installation.

2F-FLANGE MOUNT Letters are produced with a minimum 1/4” wide visible plastic flange, all around letter, to allow for installing with screws (not supplied).

OUTSIDE BRACKET MOUNT Mounting brackets are bonded to the inside return of the letter. Fasteners (not supplied) are used to screw the letter to the installation surface.